Silicon Carbide (SiC) Heating Elements

Operating Temp: Up to 1550°C

Common Range: 1100–1400°C (safe zone)

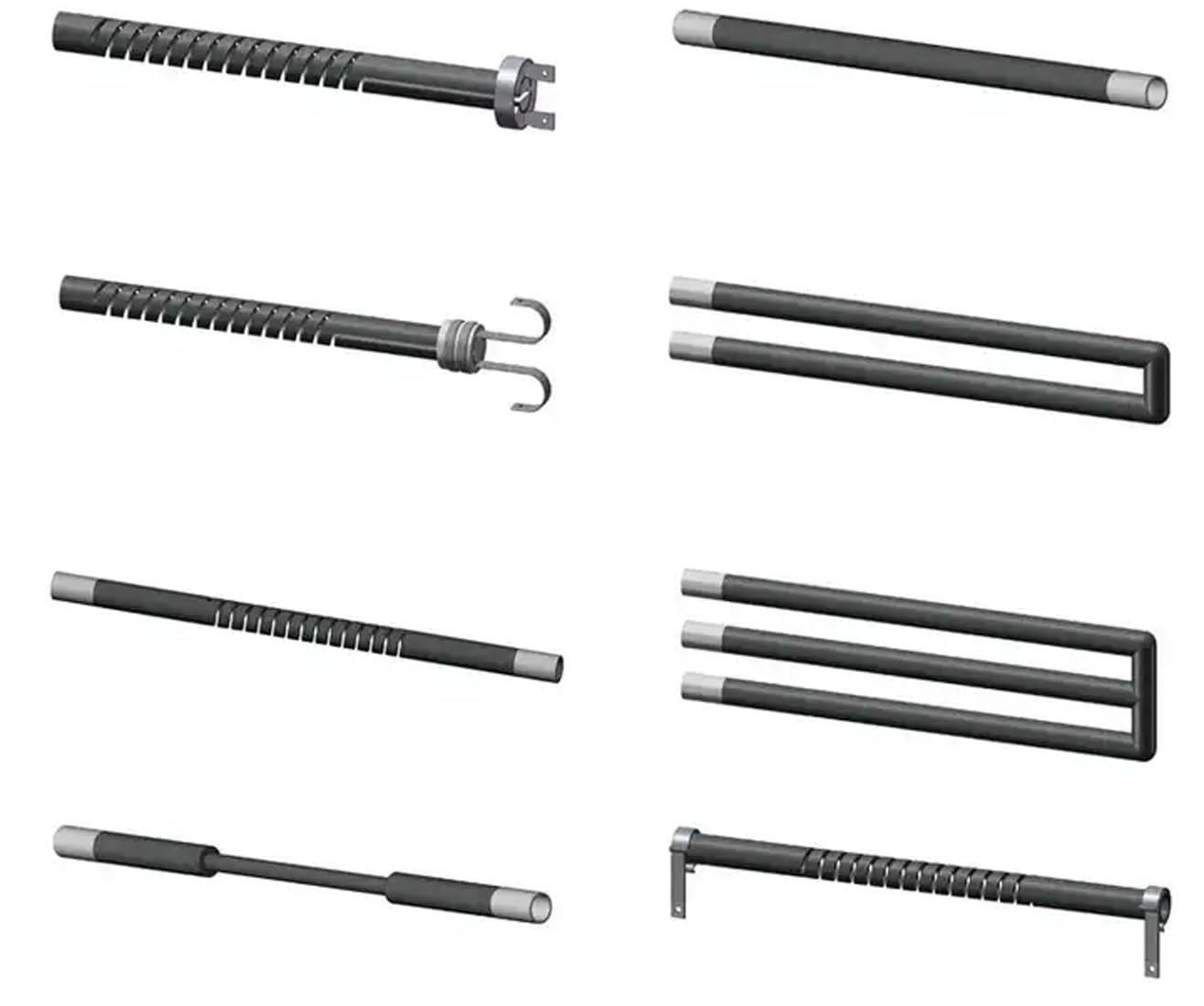

Types: Rods, U-shaped, dumbbell, spiral, bayonet

Features:

- High watt density

- Excellent thermal shock resistance

- Easy replacement

Applications: Kilns, heat treatment furnaces, glass, ceramic industries

Kanthal APM / Kanthal Super Alloys

Kanthal APM (FeCrAl Alloy):

Max temp: ~1400°C in air

More oxidation resistant than standard FeCrAl

Kanthal Super (MoSi₂-based):

Similar to MoSi₂ elements with even higher performance in oxidizing atmospheres

Selection Guidelines

| Parameter | SiC Elements | MoSi₂ Elements | Kanthal APM |

|---|---|---|---|

| Max Temp (Air) | 1550°C | 1800°C | 1400°C |

| Oxidation Resistance | Good | Excellent | Very Good |

| Mechanical Strength | Moderate | Brittle | High |

| Cost | Medium | Higher | Medium |

| Atmosphere Compatibility | Oxidizing/Neutral | Oxidizing/Neutral | Oxidizing |

Heating Element Specification Sheet

Type: Silicon Carbide (SiC) Heating Element

Application: Industrial Furnace / Kiln Heating

Temperature Range: 1250°C – 1400°C (Continuous Operation)

General Specifications

| Parameter | Description |

|---|---|

| Element Type | Dumbbell / U-shape / Straight rod (as needed) |

| Material | Recrystallized Silicon Carbide (SiC) |

| Max Operating Temp | 1550°C |

| Recommended Working Temp | 1250°C to 1400°C |

| Diameter Options | 10mm, 12mm, 14mm, 16mm, 25mm, 30mm |

| Length Range | 300 mm to 2000 mm |

| Cold End Length (S) | As per design – usually 150–300 mm |

| Hot Zone Length (H) | Customizable based on furnace design |

Electrical Specifications

| Parameter | Value (Typical) |

|---|---|

| Resistance | 0.1 – 2.0 Ω (as per length & size) |

| Watt Density | 5–20 W/cm² |

| Voltage Range | 50–400 V |

| Current Range | 10–100 A |

| Power Rating | 1–20 kW per element (typical) |

🌡️ Thermal & Mechanical Properties

| Property | Value |

|---|---|

| Thermal Conductivity | 15–30 W/m·K |

| Specific Heat Capacity | ~1.0 J/g·K |

| Maximum Surface Temp | 1600°C |

| Thermal Expansion | 4.6 × 10⁻⁶ /°C |

| Density | 2.5 – 2.8 g/cm³ |

| Oxidation Resistance | Excellent up to 1400°C |

| Atmosphere Compatibility | Oxidizing, Neutral, Partial Reducing |

🧩 Installation Notes

- High watt density

- Excellent thermal shock resistance

- Easy replacement

- Use ceramic terminal tubes for hot-end insulation

- Ensure uniform heating for long life

- Allow space for thermal expansion

- Use adjustable clamps or spring terminals

- Apply gradual startup ramping to avoid thermal shock

✅ Compliance & Standards

Conforms to IS, ASTM & DIN standards

Manufactured under ISO 9001:2015 quality systems