Refractory anchors are metallic components used to support and hold refractory linings (castables, bricks, ceramic fiber, insulation boards) onto the inner steel shell of high-temperature equipment such as furnaces, kilns, and reactors.

They ensure the mechanical stability of the refractory during thermal cycling, vibration, and chemical exposure.

Functions of Refractory Anchors

- Hold castable or plastic refractory in place

- Prevent sagging, detachment, or cracking of lining

- Absorb thermal expansion stress

- Improve bonding between the refractory lining and shell

- Reduce lining failure during vibration and thermal shock

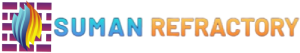

Types of Refractory Anchors

| Anchor Type | Shape Example | Application |

|---|---|---|

| V Anchor | [V Shape] | Standard castable lining. Economical and easy to weld. |

| Y Anchor | [Y Shape] | Enhanced hold in dense castables. Common in medium-duty linings. |

| U Anchor | [U Shape] | Heavy castable or dual-layer linings. Often pre-cast. |

| Bullhorn Anchor | Curved U-shape | Board or fiber lining. Flexible, used for high-temp insulation anchoring. |

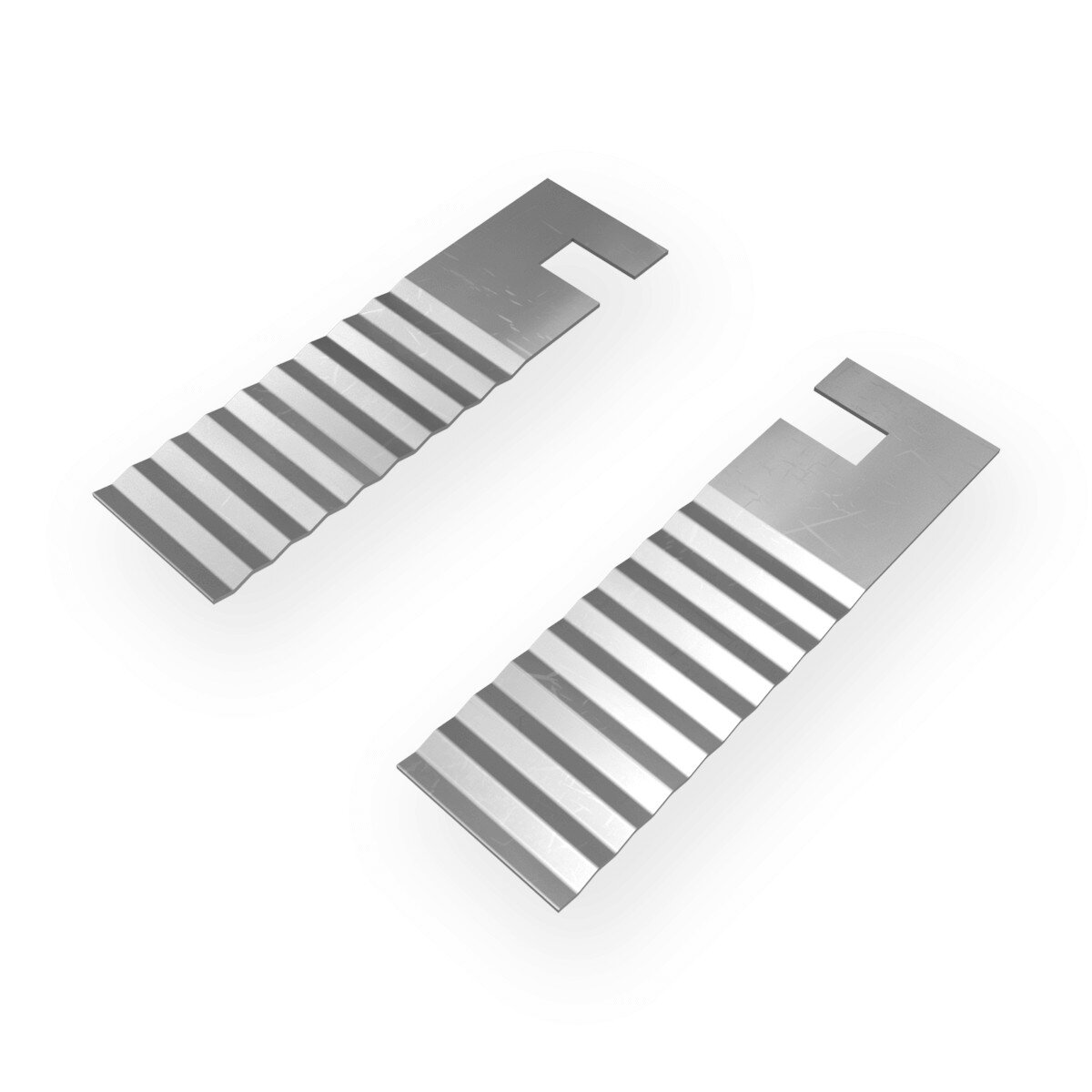

| Corrugated Anchor | Zig-zag strip | High mechanical grip in gunning and plastic refractory. |

| Twist Lock Anchor | Flat twisted strip | Quick locking systems. Used in modular lining. |

| Stud Anchor | Straight rod with welded base | Direct welding to shell or stud-welding process. |

| Hex Steel / Hexmesh | Honeycomb steel grid | Used with abrasion-resistant gunned linings, cyclones, ducts. |

Anchor selection depends on the type of refractory material, thickness, and application environment.

Materials of Construction (MOC)

| Material Grade | Max Temperature | Properties | Applications |

|---|---|---|---|

| SS 304 / 304L | ~900°C | Good corrosion resistance | General-purpose linings |

| SS 310 / 310S | ~1100°C | High-temp strength, oxidation resistance | Furnaces, kilns |

| SS 316 / 316L | ~925°C | Acid-resistant, chloride protection | Chemical & fertilizer industry |

| Inconel 600 / 601 | ~1150°C | Excellent corrosion & heat resistance | Petrochemical, critical environments |

| Alloy 330 | ~1150°C | Oxidation resistance at high temps | Reformers, cracking units |

| Kanthal (FeCrAl) | ~1300–1400°C | Very high-temp and oxidation resistance | Special heaters, incinerators |

| Carbon Steel | ~450–600°C | Low cost, temporary applications | For pre-cast blocks or low-temp use |

Design Parameters

- Length of Anchor = ~75–300 mm (depends on refractory thickness)

- Rod Diameter = 6 mm, 8 mm, 10 mm, 12 mm

- Spacing (c/c) = 150–400 mm

- Density = 4–10 anchors per square meter depending on thickness

Selection Tips

- Shorter anchors = for thinner linings (<100 mm)

- Longer & robust anchors = for thicker monolithic linings (>150 mm)

- Use expansion loops or bends to absorb thermal movement

Applications

Refractory anchors are used to hold different refractory systems:

- Castable Refractory Lining

- Plastic Refractory

- Ceramic Fiber Modules

- Insulating Boards / Panels

- Gunned Lining

- Dual-Layer Linings (Hot-face + insulation)

They are installed by manual welding, stud welding, or bolting.

Industries Using Refractory Anchors

| Industry | Application Area |

|---|---|

| Steel Industry | Reheating furnaces, ladles, tundish covers |

| Cement & Lime | Kilns, calciners, tertiary ducts |

| Petrochemical | Reformer furnaces, FCC units, heaters |

| Power Plants | Boilers, ESPs, ducts |

| Non-Ferrous Metals | Aluminum & copper melting furnaces |

| Glass Industry | Forehearths, regenerators |

| Chemical Plants | Sulfuric acid plants, fertilizer units |

| Waste Treatment | Incinerators, gasifiers, pyrolysis plants |

| Foundries | Heat treatment furnaces, annealing chambers |